ASA

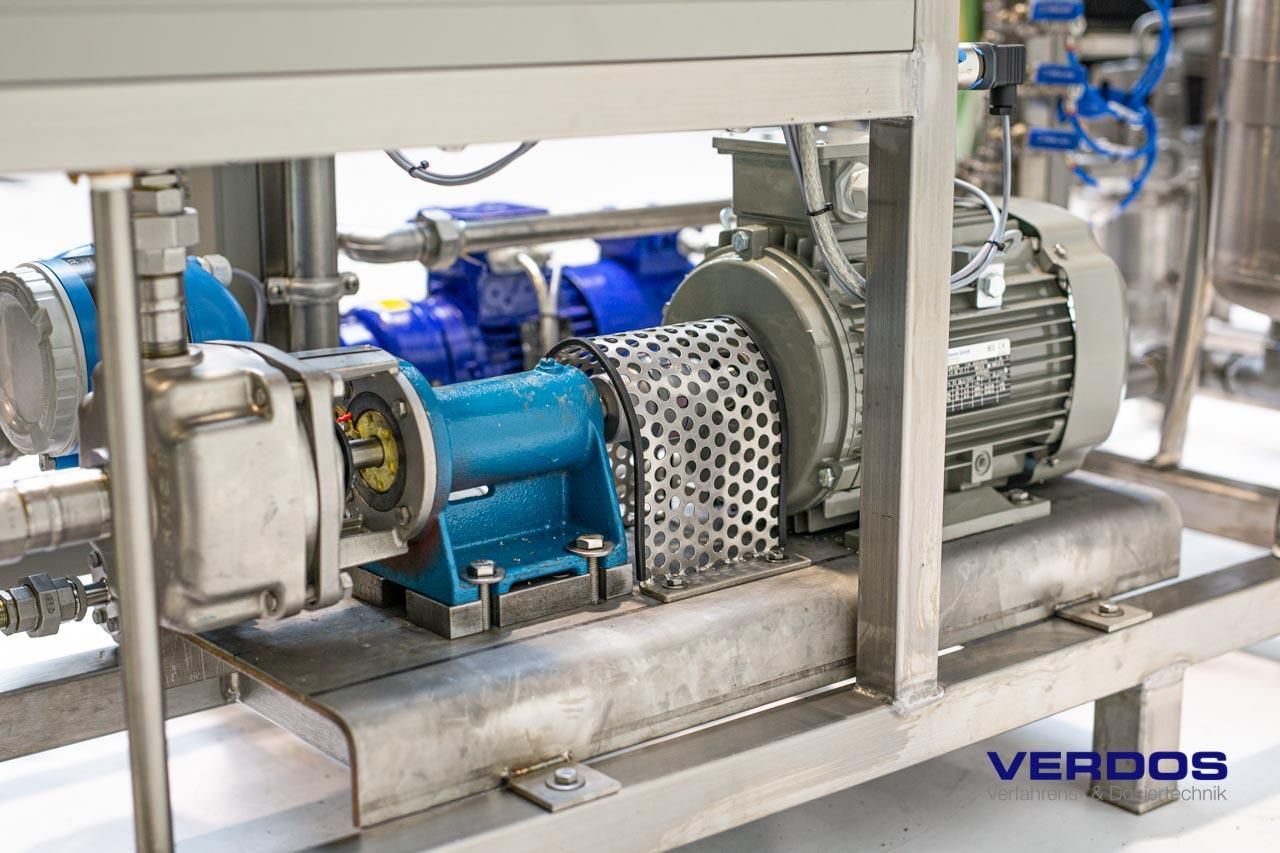

Emulsifying Machines

The compound system for ASA size

The most modern and paper-friendly process is the synthetic sizing process. Usually AKD glue (alkyl ketene dimer) or ASA glue (alkenyl succinic anhydride) is used to make it writable or printable with printing ink. On the one hand, the sizing reduces the internal surface tension, on the other hand, the tear strength of the paper is significantly increased.

Our ASA systems are designed for the production of a homogeneous ASA emulsion on a starch/ASA or water/polymer ASA basis.

Filsize Feeder FS-15

The Filsize Feeder FS-15 is a fully automatic system for the preparation of a highly effective ASA emulsion on a starch/ASA or water/polymer ASA basis.

The starch is introduced by means of a starch dosing system.

This Verdos-developed system produces a ready-to-use emulsion for online dosing.

Through multilayer dosing, the emulsion can be applied to any number of layers in a fully automatic process.

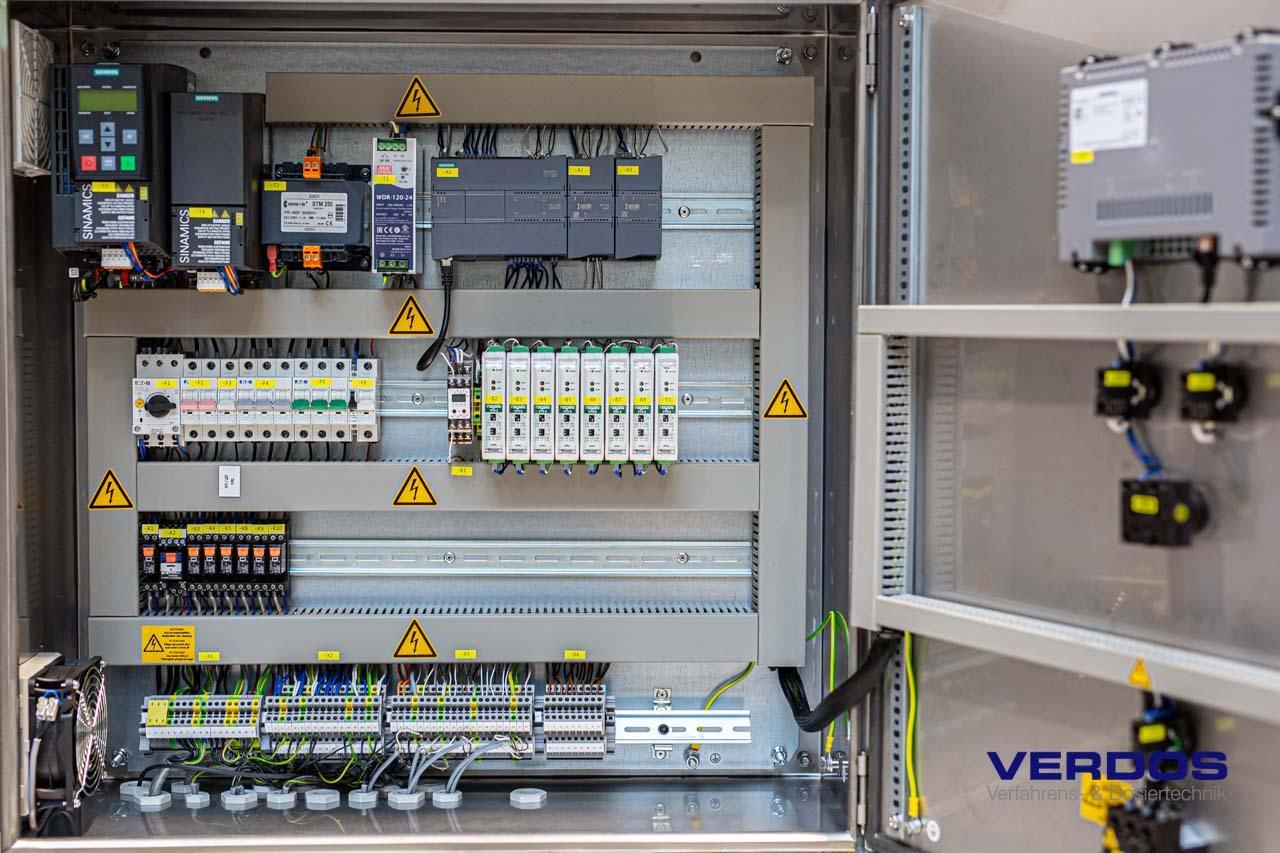

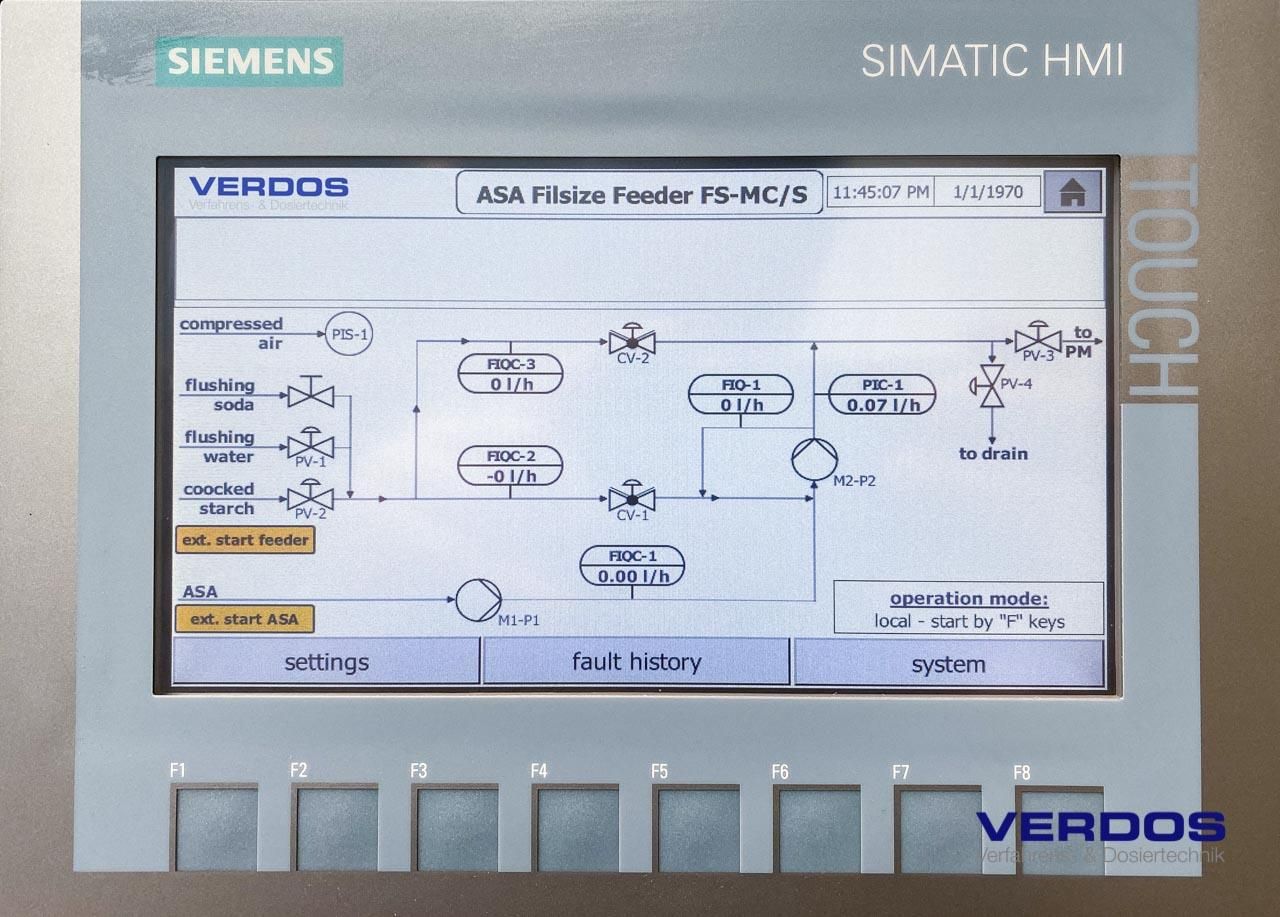

The system is controlled via a Siemens Simatic PLC. Via the touch panel, all parameters required for optimum operation can be entered and all process data can be monitored.

The flow rates of all media are PID controlled. This way, the user only has to specify the required quantities on the touch panel or from an external device via 4-20mA signal or bus.

| Type | Filsize Feeder FS-MC | |

|---|---|---|

| Total emulsion l/h | 50 - 5000 | |

| Emulsifying machine kW output | 22 | |

| Primary flow rate starch l/h | 50 - 250 | |

| Secondary flow rate starch l/h | 0 - 5000 | |

| ASA l/h | 10 - 100 | 15 - 200 |

| Polymer l/h | 10 - 100 | 15 - 200 |

| Max. starch infeed temperature | 85°C | |

Data and facts:

- Particle size 0.8 – 1.5 µm

- Coriolis mass flow measurement of the ASA size

- Built-in plate heat exchanger for cooling of the primary feed volume

- Closed mixing system

- Fully PID controlled

- Primary and secondary starch

- ASA

- Secondary dilution

- Primary starch is temperature controlled

- Calibration cylinder with siphon pump

- Siemens Simatic PLC with touch panel

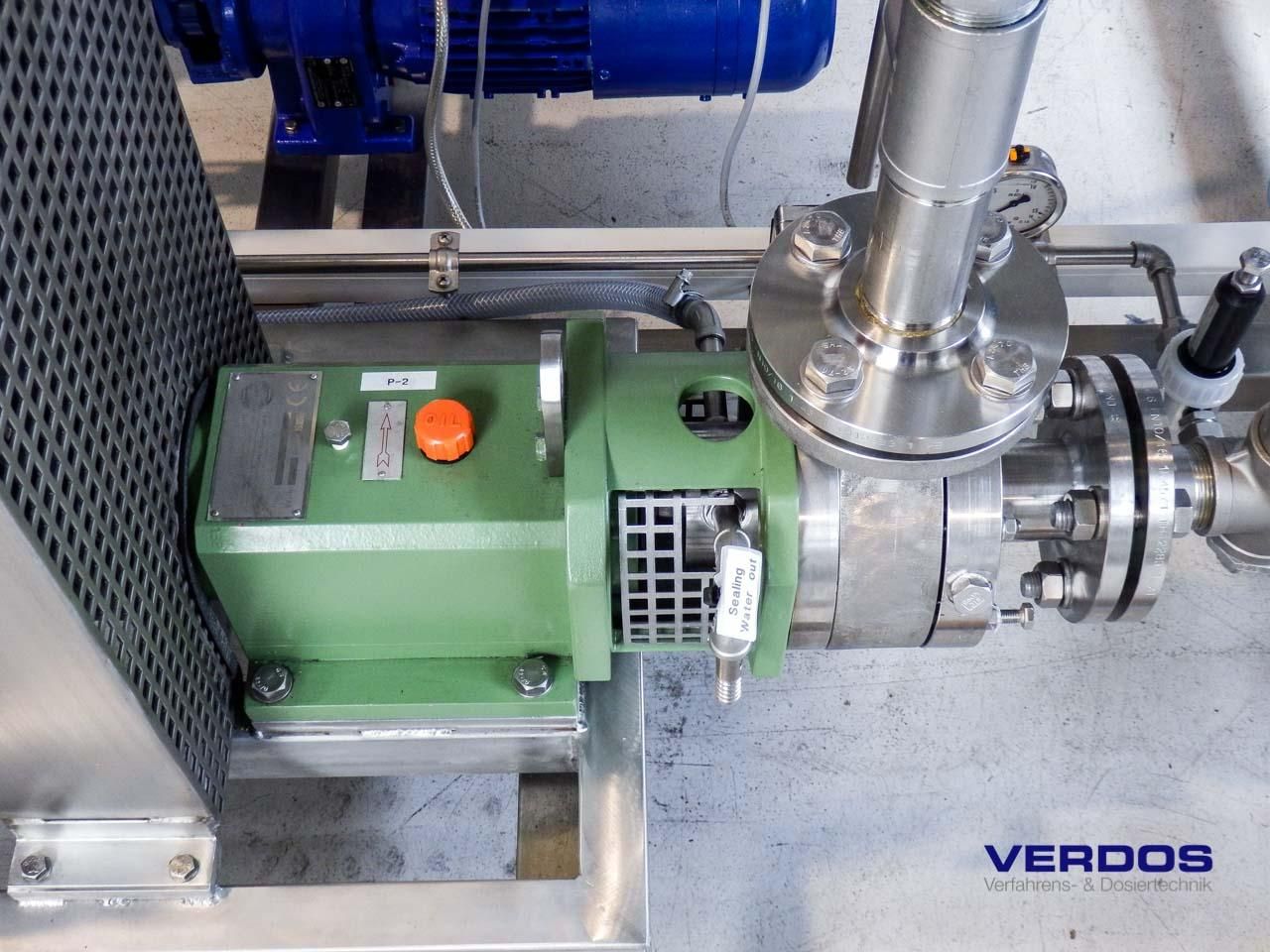

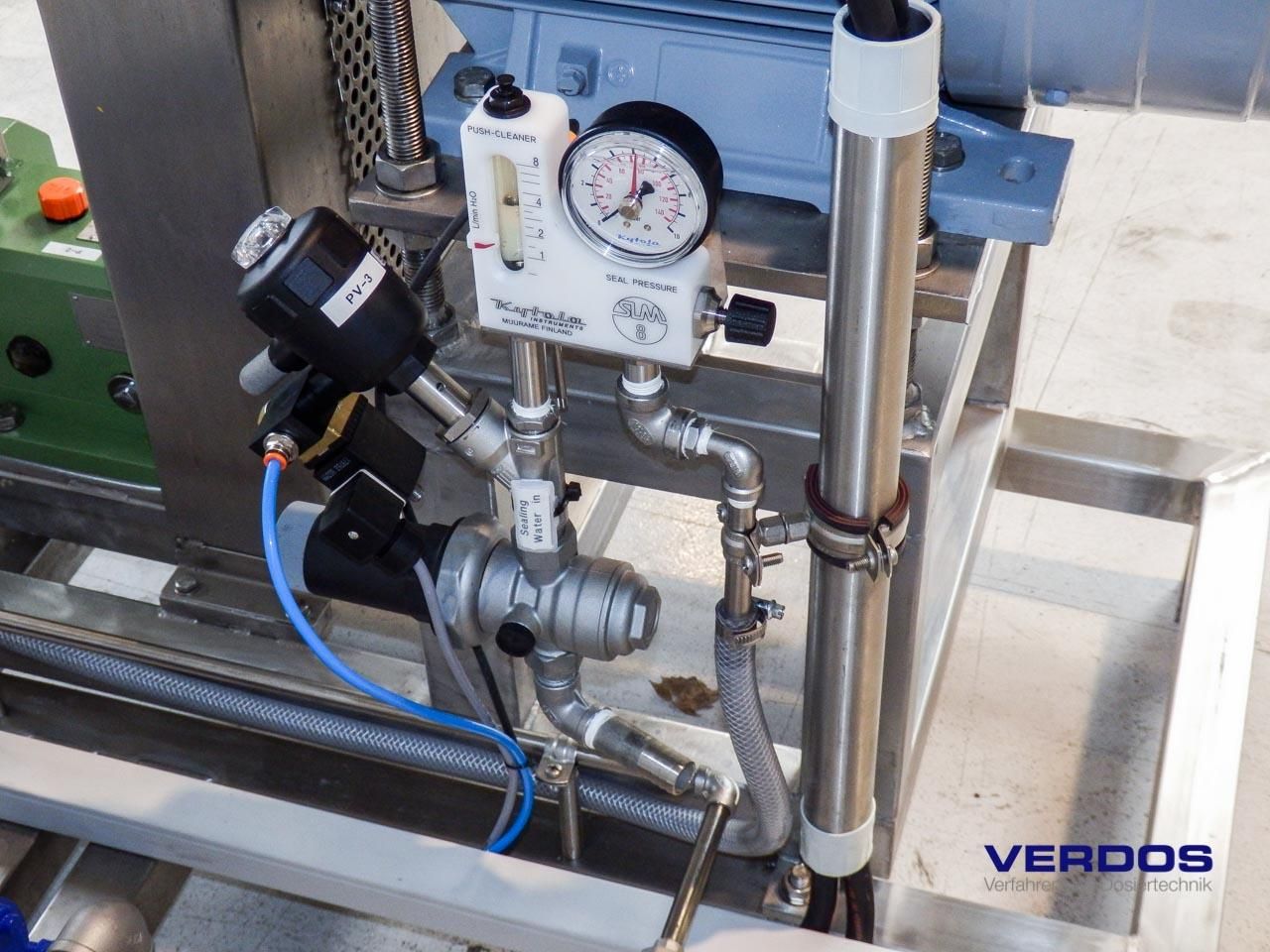

- Chassis and piping made of high-quality stainless steel

Further options:

- Double filter unit with differential pressure gauge

- Mechanical filtering of the inlet feed starch

- Mechanical filtering of the ready-to-use ASA emulsion

- Starch dosing system for the autonomous starch supply of the ASA system, with flow meter as well as a water and lye rinsing unit.

- Automatic lye and water rinsing unit

- Manifold

- Any number of control valves and inductive flow meters

- Fully automatic due to PID control

- ASA product filter

- BUS communication

- Smaller emulsifying machine with 5.5 instead of 22 kW

Filsize Feeder FS-MC

Mechanically controlled

The Filsize Feeder FS-MC is a semi-automatic system for the preparation of a highly effective ASA emulsion on a starch/ASA or water/polymer ASA basis.

Therefore, this system is a cost-effective alternative to the Filsize Feeder FS-15.

The Filsize FS-MC is used for smaller installations.

The ASA flow rate is maintained by a frequency converter controlled dosing pump and monitored by a flow switch.

The starch is introduced by means of a PID controlled starch dosing system.

This Verdos-developed system produces a ready-to-use emulsion for online dosing.

The system is controlled via a Siemens Simatic PLC. Via the touch panel, all parameters required for optimum operation can be entered and all process data can be monitored.

| Type | Filsize Feeder FS-MC | |

|---|---|---|

| Total emulsion l/h | 50 - 500 | |

| Emulsifying machine kW output | 5,5 | |

| Starch l/h | 50 - 500 | |

| ASA l/h | 6 - 60 | |

| Polymer l/h | 6 - 60 | |

| Max. starch infeed temperature | 85°C | |

Data and facts:

- Built-in plate heat exchanger for starch cooling

- Closed mixing system

- PID controlled starch flow

- Frequency converter controlled ASA dosing pump

- ASA flow monitoring

- Calibration cylinder with siphon pump

- Siemens Simatic PLC with touch panel

- Chassis and piping made of high-quality stainless steel

Further options:

- ASA flow measurement, by means of Coriolis or gear wheel flow meter

- Double filter unit with differential pressure gauge

- Mechanical filtering of the inlet feed starch

- Mechanical filtering of the ready-to-use ASA emulsion

- Starch dosing system for autonomous starch supply to the ASA system

- Water and lye rinsing unit

- ASA product filter

- BUS communication