Twindos

The dry polymer dissolver unit for retention - batch system

The Twindos is an automatic powder polymer dissolver unit for the production of a highly effective polymer solution, which is used in retention as well as in other applications.

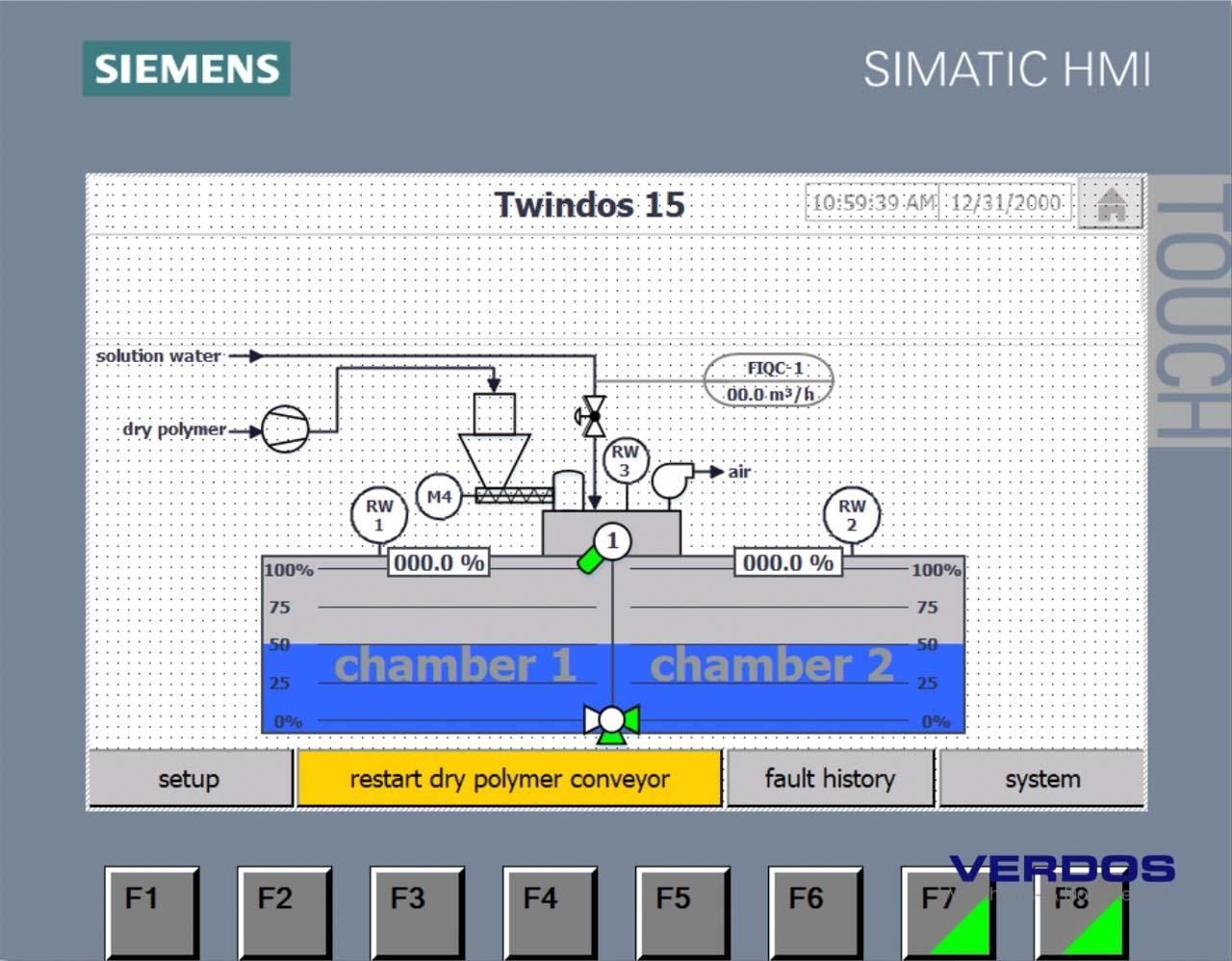

An alternating operation of the two maturation or dosing chambers ensures a flocculant maturation time of 60 minutes.

The flocculant is injected into the batch chamber through the dry product dosing device.

The wetting device provides for a homogeneous wetting of the product.

The wetted product is then fed into the draught tubes of the Verdos agitator system. Upon reaching an optimum mixing ratio, the product overflows into the maturation chamber, where it is gently homogenised and provided as the matured product.

The resulting polymer solution can now be injected into the process as a ready-to-use solution through the dosing pumps without intermediate tanks.

An alternating operation of the two maturation or dosing chambers ensures a maturation time of 60 minutes.

The system can be used either with dry or liquid media.

The system is controlled via a Siemens Simatic PLC. The touch panel can be used to enter all parameters required for optimum system operation and to monitor all process data, ensuring the preparation of a consistent polymer solution.

Twindos in standard design:

| TypE | Twindos |

|---|---|

| Dissolving capacity | 1000 – 15000l/h |

| Polymer capacity | 5-75 kg/h |

| Solution concentration | 0,1 – 0,5% |

Data and facts:

- Two chambers (maturation and dosing chambers) in high-quality stainless steel design, for alternating operation

- One agitator per chamber

- Heated screw conveyor

- Wetting device developed by VERDOS

- Draught tube agitator system developed by VERDOS

- 100 l storage hopper

- PID controlled water flow path with inductive flow meter and control valve

- One level control per chamber

- High-quality stainless steel piping

Custom sizes available on request.

Further options:

- Big-Bag lifting frame with or without crane

- Granulate suction unit

- Storage container for dry polymer, bag discharge or with Big Bag frame

- Pressure booster station for dilution water

- Dosing system for polymer solution

- Secondary dilution units for further reduction of the solution concentration

- Double filter unit with differential pressure gauge for polymer solution filtration

- Liquid polymer dosing pump

- Coriolis or inductive flow meter for PID controlled liquid polymer supply

- Air conditioning unit for switch and control cabinet