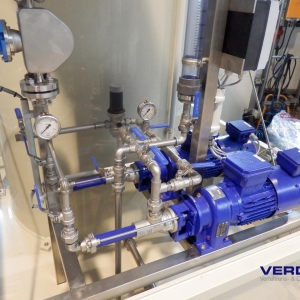

IBC Mother-Daughter Systems

IBC, Decanting, Storage & Dosing Station

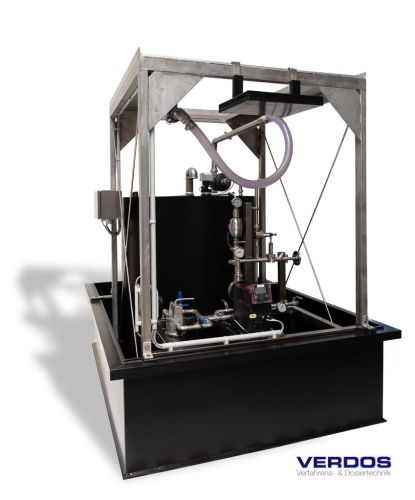

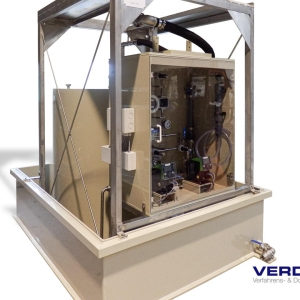

Our mother-daughter systems, decanting and storage stations are automatic decanting and storage systems for chemicals. The storage system can be expanded with a dosing system and is therefore a compact decanting, storage and dosing station.

Read more...

The advantage:

- The fill level of the storage tank is constantly kept at almost full(the desired level can be adjusted)

- Output of an order message regarding a required IBC replacement. At this time, the storage tank fill level is still at least 60%. This ensures that the IBC does not have to be replaced immediately (depending on the withdrawal quantity).

- Can be expanded with a dosing system with any number of dosing lines, mounted inside the drip tub

Data and facts:

- Systems for the production, treatment and use (HBV systems) according to German Federal Water Act (WHG)

- Drip tub PP, PE, V2A or V4A with leakage detector

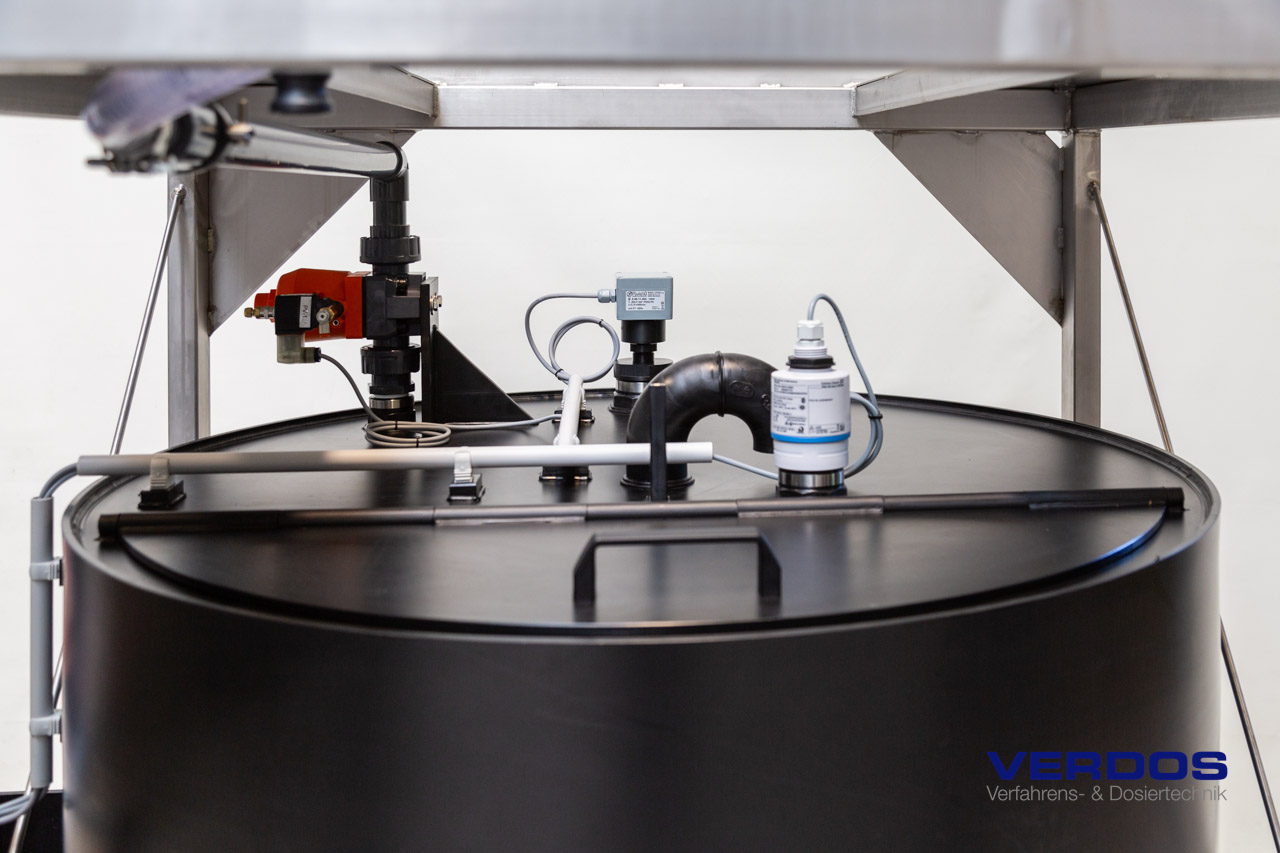

- Storage tank with 1200-1400l effective volume, featuring:

- Material: PP, PE, V2A or V4A

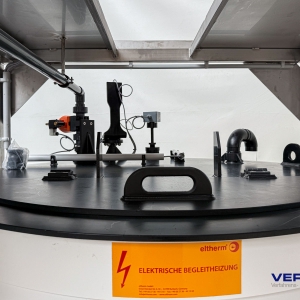

- Pressure transmitter for level detection

- Overfill prevention

- 1/3 of the lid is foldable

- Incl. all necessary connections (flange, socket, venting elbow, etc.)

- VA chassis for placement of an IBC container

- Inclined design, for complete draining of the IBC container

- Automatic product decanting

- Quick coupler provides for nearly drip-free IBC container replacement, with drip tub

- Switch and control cabinet with touch display for level indication

- Output of an order message

- Output of the fill level via 4-20mA signal

Options:

- Agitator

- Dosing system, mounted inside drip tub

- Siemens PLC with KTP700 touch panel